8K vs 16K Resin 3D Printer: All You Need to Know

piocreat3d

on

August 26, 2024

In the world of resin 3D printing, resolution plays a pivotal role in determining the quality and detail of your prints. As the demand for more intricate and high-precision designs grows, manufacturers have developed 8K and 16K resin 3D printers to meet these needs. But what do these resolutions mean, and how do they impact your printing projects?

In this article, we’ll dive into the specifics of 8K and 16K resin 3D printers, comparing their features, applications, and the benefits they bring to various industries. By the end, you’ll have a clear understanding of which printer might be the best fit for your projects.

Does Resin Printer Resolution Matter?

Yes, resolution is a crucial factor when it comes to resin 3D printing, particularly with LCD (or MSLA) printers. In these printers, a UV light source passes through an LCD screen that masks parts of the light to create precise layers of your print based on the design file. This process is highly dependent on resolution, which determines how detailed and sharp the final print will be.

A good resin 3D print resolution typically ranges between 0.05 to 0.2 millimeters, equivalent to 50 to 200 microns. The lower the micron count, the finer the details you can achieve. For intricate designs such as jewelry or dental models, high resolution (around 50 microns) is essential. On the other hand, for larger models where extreme precision is less critical, a lower resolution might suffice.

Thus, resin printer resolution does indeed matter, especially if your project demands sharp detail and intricate craftsmanship.

What Does 8K Mean in 3D Printing?

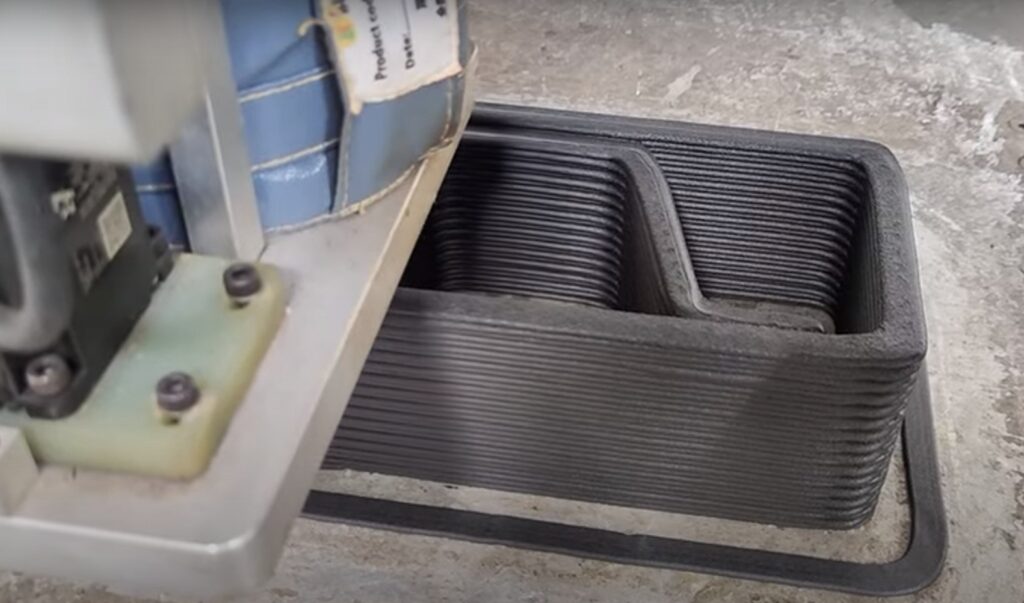

An 8K resin 3D printer is designed to deliver highly detailed and precise prints. The “8K” refers to the screen resolution used in the printer, with a total pixel count significantly higher than lower-resolution models. Specifically, an 8K resolution has roughly 7,680 x 4,320 pixels, translating to a level of detail four times that of a 4K printer.

What this means for your printing projects is enhanced precision and clarity, particularly when creating complex or intricate designs. Whether you’re working on detailed prototypes, figurines, or small-scale models, the 8K resolution ensures that every tiny detail is captured and rendered in high definition.

What Does 16K Mean in 3D Printing?

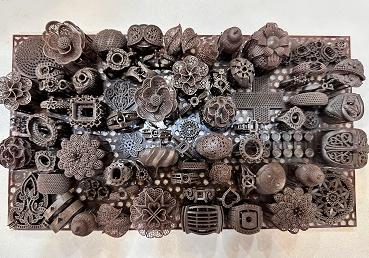

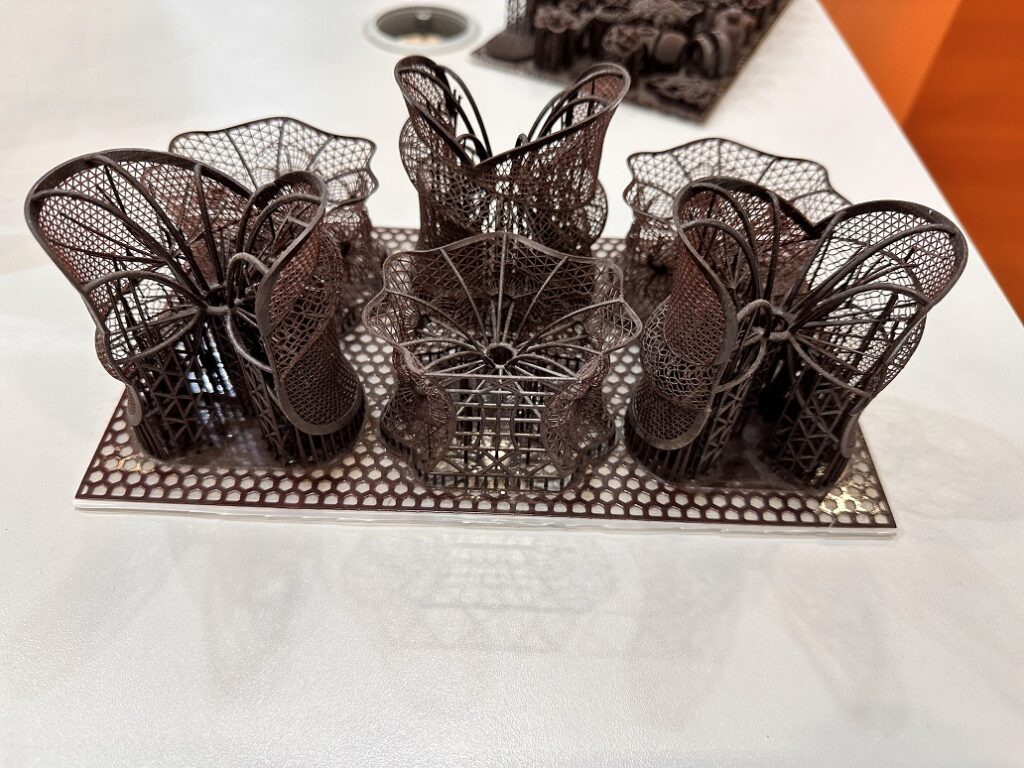

Taking things even further, a 16K resin 3D printer boasts an even higher resolution than its 8K counterpart. The “16K” refers to a display resolution of 15120*6230 pixels, which allows for unparalleled detail and accuracy in prints.

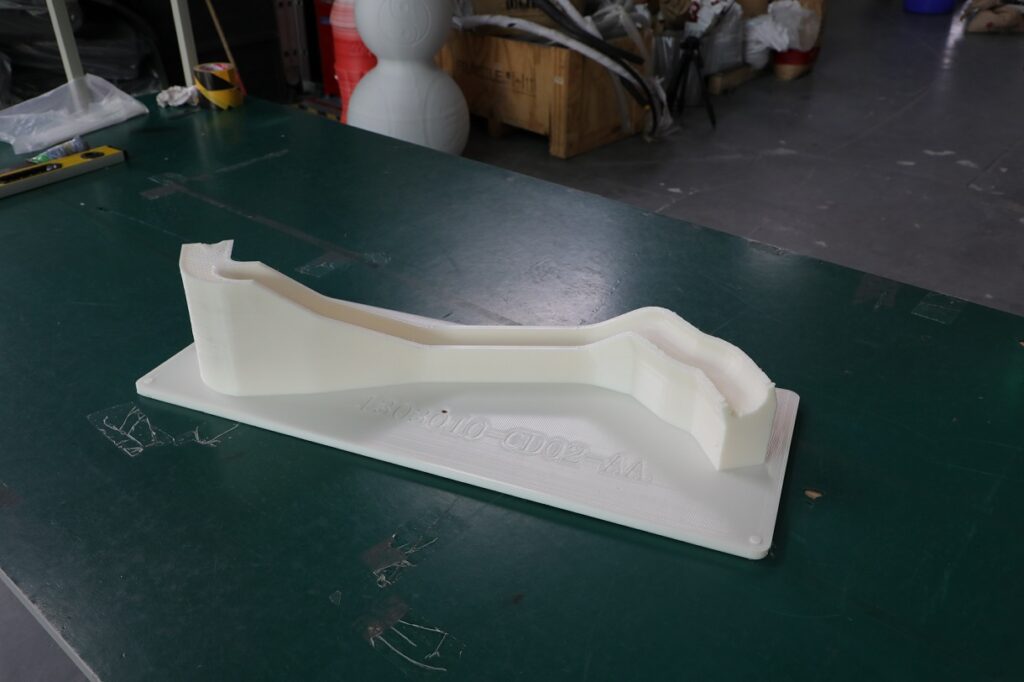

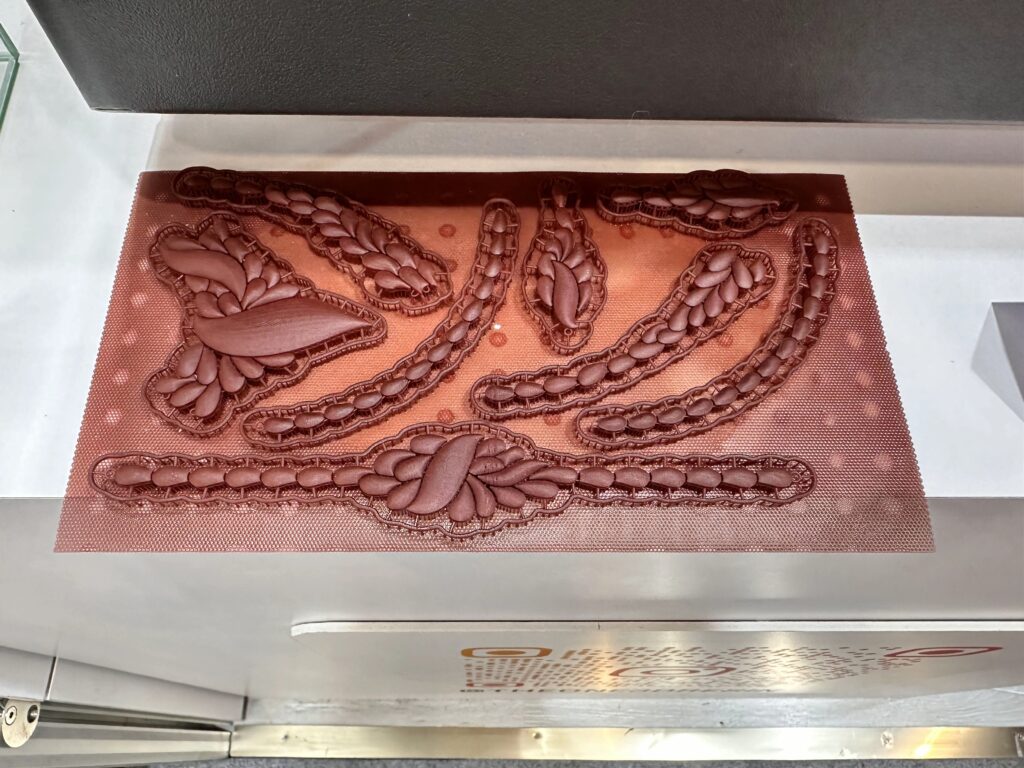

This technology is especially useful in industries where precision is paramount, such as jewelry making, dentistry, and industrial design. The extremely fine pixel density ensures that no detail is lost, making it ideal for professionals who need to create highly intricate and accurate models. Whether you’re producing a dental crown or an ornate piece of jewelry, the 16K printer delivers exceptional results.

Is 16K Better Than 8K?

The question of whether 16K is better than 8K largely depends on your specific needs and the type of projects you’re working on. Both 8K and 16K printers offer incredible resolution and can produce high-quality prints, but 16K printers take it one step further in terms of precision.

If your projects demand the utmost accuracy, such as fine jewelry or detailed dental models, then a 16K printer is undoubtedly the better choice. The higher resolution means that even the smallest details are captured flawlessly. On the other hand, if you don’t require extreme precision and would prefer a more budget-friendly option, an 8K printer is still an excellent choice for most high-detail applications.

In short, while 16K offers superior resolution, 8K still provides impressive quality and may be more than enough for most users.

Best 8K Resin 3D Printer

For those interested in 8K resin 3D printers, one standout model is the PioCreat DJ89 PLUS. This printer features a 10.3-inch 8K LCD with a pixel size of 29μm. This high resolution ensures that even the most intricate designs, such as dental models or fine jewelry, are captured in stunning detail.

The PioCreat DJ89 PLUS is particularly well-suited for applications where precision and detail are crucial. Whether you’re working on complex dental structures or crafting fine jewelry, the sharp resolution and reliable performance make it an excellent choice.

Key features of the PioCreat DJ89 PLUS include:

- 10.3-inch 8K LCD

- 29μm pixel size

- High-detail sculpting for intricate designs

- Ideal for dental and jewelry applications

Best 16K Resin 3D Printer

If you’re seeking the absolute pinnacle of resin 3D printing technology, the PioCreat HALOT-X1 is a top-tier 16K resin 3D printer. This groundbreaking printer combines zero-calibration readiness, industrial-grade stability, and intelligent exposure control to empower creators like never before. The HALOT-X1 delivers flawless results from the first layer to the final twist of its quick-release build plate.

At the same time, it features dual linear rails & dual lead screws, ensuring stable performance across tall and detailed prints. Combine that with a maximum speed of 170mm/h at 0.2mm layer height, it outpaces many 16K printers that are larger, heavier, and slower.

Key features of the PioCreat HALOT-X1 include:

True Leveling-Free

Enhanced Stability and Precision

92 Light Zones Intelligent Exposure

16K Mono LCD Ultra-High Resolution

Conclusion

When it comes to 3D printing, especially with resin printers, resolution is a critical factor that determines the quality of your prints. Both 8K and 16K resin 3D printers offer impressive precision, with 16K pushing the boundaries of detail even further.

For most users, an 8K printer will provide more than enough detail for intricate designs and prototypes. However, if you’re in an industry that demands the highest level of accuracy and detail—such as jewelry design or dental modeling—a 16K printer is the clear winner.

Choosing between an 8K and 16K printer ultimately comes down to your specific needs and budget. But one thing is certain: both options offer cutting-edge technology that will help you bring your most detailed designs to life.