Whether streamlining surgical processes or advancing medical education and preparation, the GS01 FDM 3D Printer is your innovative partner, delivering top-tier results, reducing surgical risks, and leading to overall enhanced procedural outcomes. Explore how the GS01 can redefine the future of your medical and surgical projects.

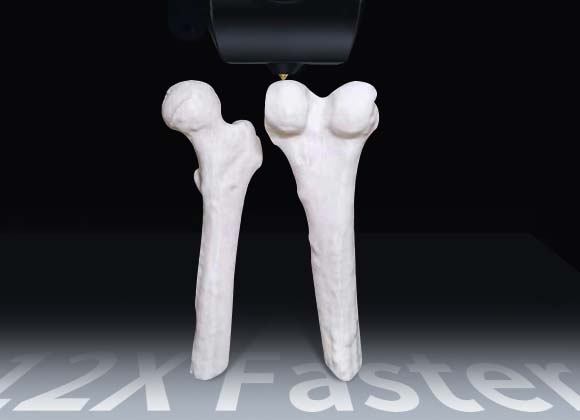

The GS01 offers a dazzling print speed of up to 600mm/s, supported by an extraordinary acceleration of 20,000mm/s², making it approximately 12 times faster than conventional models.

Equipped with a high flow 32mm³/s nozzle, the GS01 heats up to 200°C in just 40 seconds. This feature ensures thorough melting of materials even at high speeds, guaranteeing excellent print quality every time.

With an integrated vibration sensor, the GS01 effectively controls resonance, enhancing the texture and consistency of each layer, resulting in superior print clarity and fidelity.

| GS01 FDM 3D Printer Parameters | |

|---|---|

| Moldingt echnology | FDM |

| Print size | 300×300×300mm |

| Print layer thickness | 0.1-0.35mm |

| Printing accuracy | 100土0.1mm |

| Printing speed | ≤600mm/s |

| Printing material | ABS/PLA/PETG/PET/TPU/PA/ASA/PC |

| Acceleration | ≤<20000mm/s2 |

| Nozzle temperature | ≤320°C |

| Heating bed temperature | ≤120°C |

| Extruder type | Dual gear proximal extruder |

| Nozzle diameter | 0.4mm (optional 0.6/0.8mm) |

| Filament diameter | 1.75mm |

| Discharging mechanism | Screw extruder |

| Slicing software | Plocreat slicer |

| Rated power | 1000W |

| Power requirements | 100-240V~,50/60Hz |

| N.W. | 18KG |

| G.W | 23KG |

| Warranty | 12 months manufacturer's warranty |

| Technical Support: | Unlimited lifetime technical support |

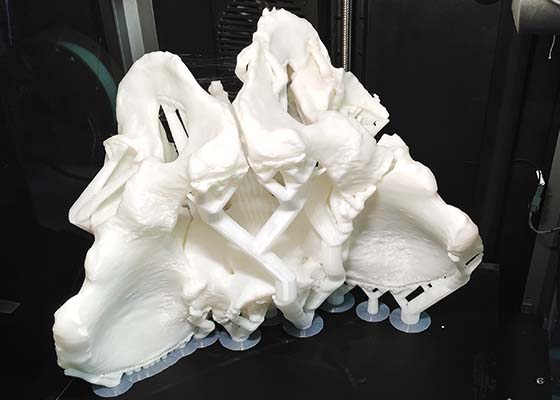

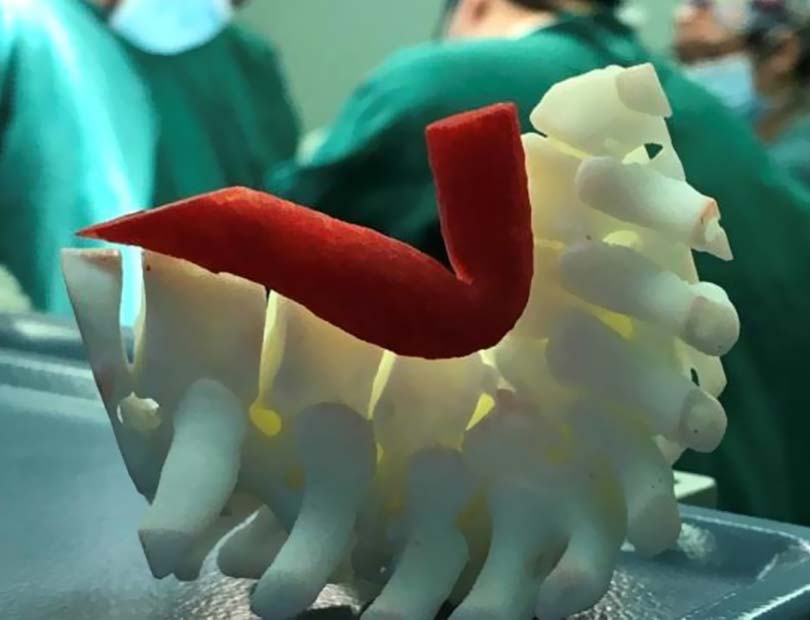

It can be used for preoperative surgical planning or surgical rehearsal,as well as preoperative matching of individualized implants. Surgical training models for various disease states can be designed and printed according to the doctor’s requirements.

cases

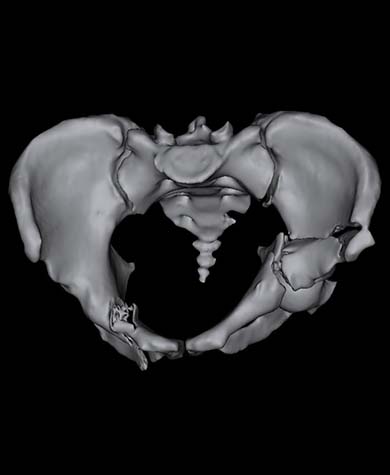

The patient’s MR examination revealed a huge bone tumor in the pelvis, and he was subsequently scheduled to be hospitalized for surgical removal.

In order to have a reference to the actual size of the tumor during surgery, doctors recommend that 3D printing be used to create a model including the tumor, aorta, and adjacent parts in vitro before surgery for intraoperative reference.

Clinical results show that the 3D model group has shorter operation time, less intraoperative bleeding and postoperative drainage than the non-3D model group, improves surgical accuracy, shortens operation time, and achieves better surgical results.

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.