PioCreat Wraps Up a Successful RAPID + TCT 2024!

piocreat3d

on

June 28, 2024

From June 25th to 27th, 2024, Piocreat proudly showcased its latest innovations at RAPID + TCT 2024, held at the Los Angeles Convention Center. Our booth 2909, was a hub of excitement and innovation, drawing in professionals and enthusiasts from across the globe. Here’s a recap of the highlights from our participation in North America’s premier additive manufacturing event.

Piocreat is a new star in the 3D printing industry, focusing on the research, development, production, and sales of advanced 3D printers for dentistry and large-size additive manufacturing. Our commitment to innovation and excellence was on full display at RAPID + TCT 2024.

Highlights from Our Booth 2909

Our booth featured cutting-edge 3D printing solutions designed to meet the diverse needs of our clients, particularly in the dental and industrial sectors. Here are the standout products we showcased:

Dental 3D Printing Solution

- Integral Light Source: Delivers 90% light uniformity for consistent results.

- High Resolution: 8K 10.3″ LCD with a 29μm pixel size for precise prints.

- Advanced Features: Heating chamber, automatic feeding, and a stable Z-axis ensure precision and cost-effective production.

- Efficient Production: Designed specifically for dental applications, offering high-quality output and reliability.

UV02 High-Speed UV Curing Machine

- Perfect Curing: Controlled light for curing professional dental resins in just 1-5 minutes.

- Specialized Design: Tailored for the dental industry, ensuring optimal results and efficiency.

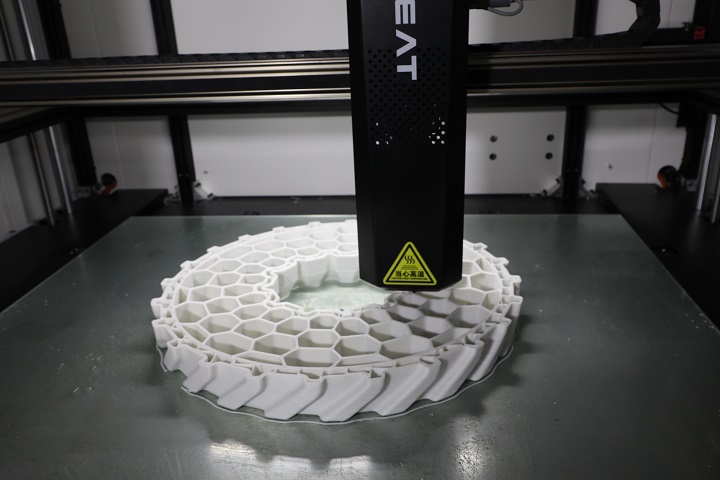

Pellet 3D Printing Solution

- Large Build Size: 1200x1000x1000mm capacity for extensive projects.

- High-Performance Components: 450°C nozzle, 120°C rapid hot bed heating, high flow screw extrusion, and a powerful servo motor.

- Cost-Effective: Utilizes low-cost pellet feedstocks, reducing material costs by over 60%.

- Compact and Versatile: Desktop model with a 500 x 500 x 400mm build size.

- Advanced Capabilities: 400°C nozzle, 120°C rapid hot bed heating, and high-speed printing for diverse materials.

- Economic Efficiency: Uses low-cost pellet feedstocks, significantly lowering material costs.

Looking Ahead

As we wrap up our presence at RAPID + TCT 2024, we are more excited than ever about the future. Piocreat remains dedicated to pioneering advancements in 3D printing technology, continually striving to meet the evolving needs of our customers and the industry.

Thank you to everyone who visited us at booth 2909. We look forward to continuing our journey of innovation and excellence together!

For more information and updates, visit www.piocreat3d.com.