Recap of the Greater New York Dental Meeting 2024

piocreat3d

on

December 5, 2024

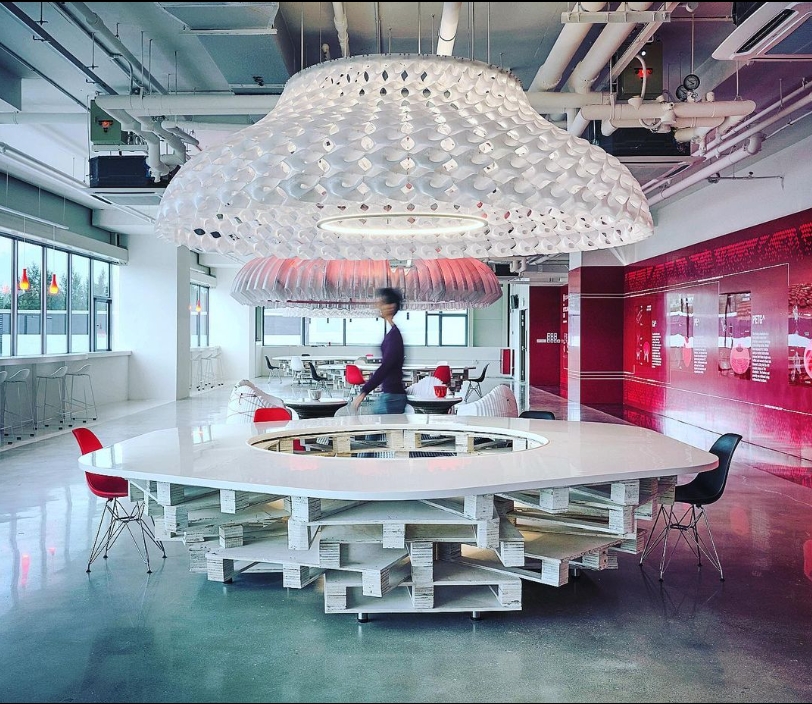

The Greater New York Dental Meeting 2024 has officially wrapped up, and it was an extraordinary event for PioCreat!

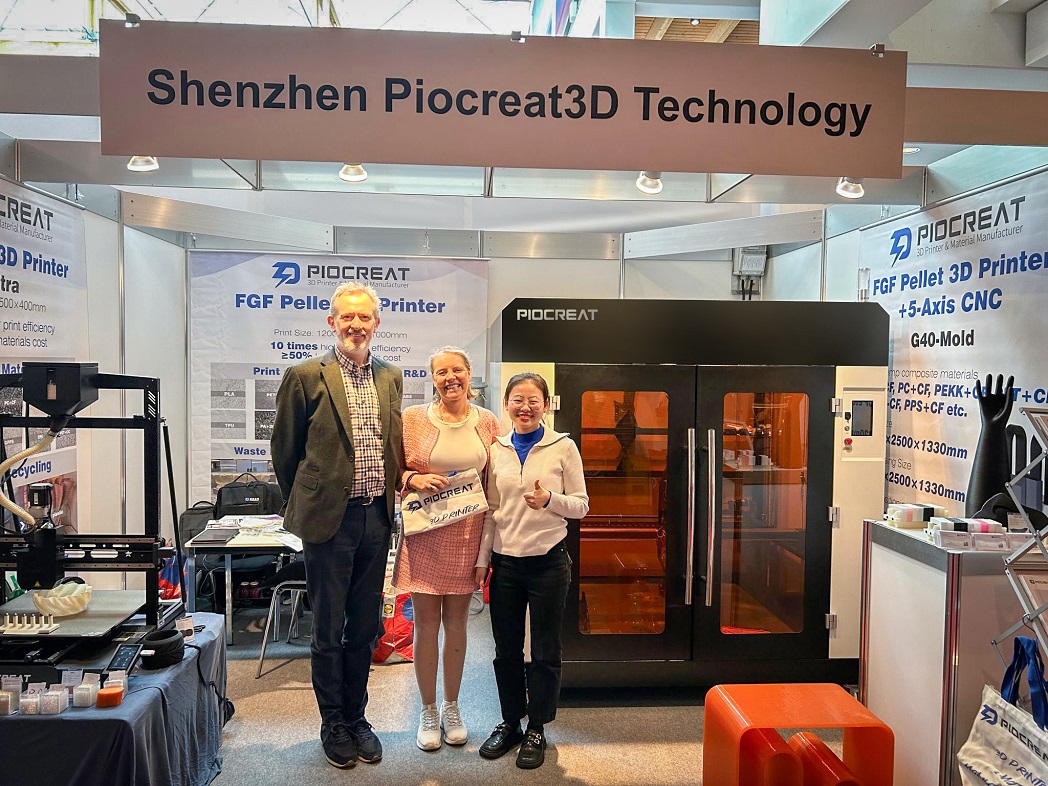

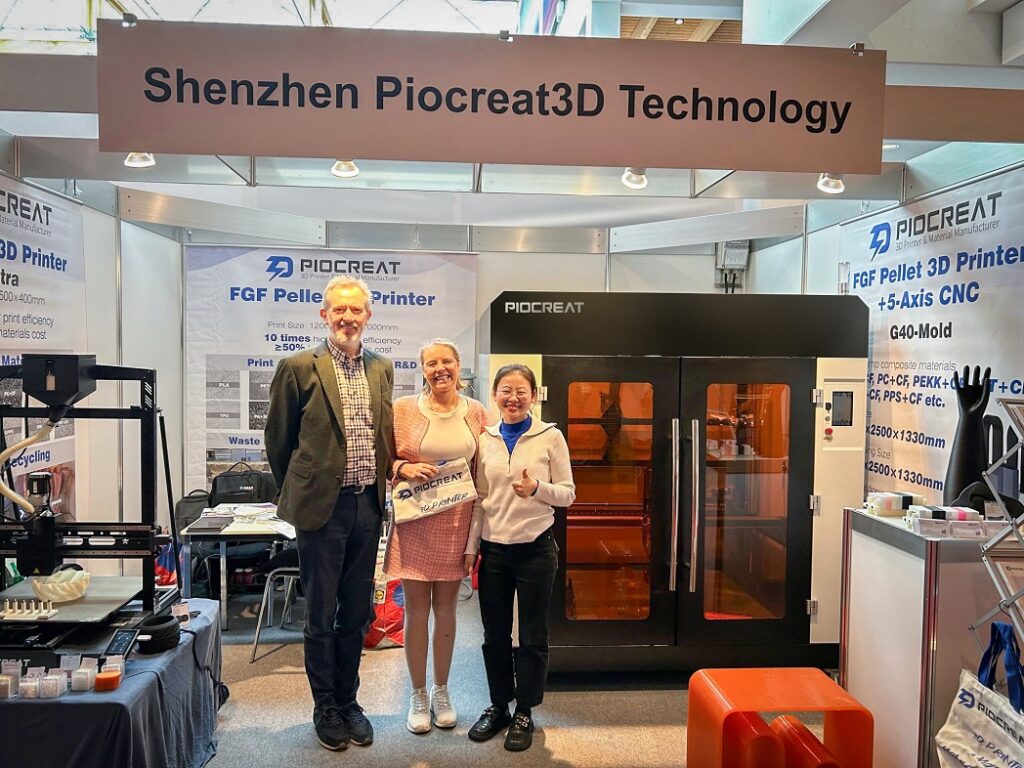

In partnership with Global Synergy Advisors, we proudly showcased our state-of-the-art dental 3D printing solutions, offering visitors a glimpse into the future of digital dentistry.

Showcasing Innovation in Dental 3D Printing

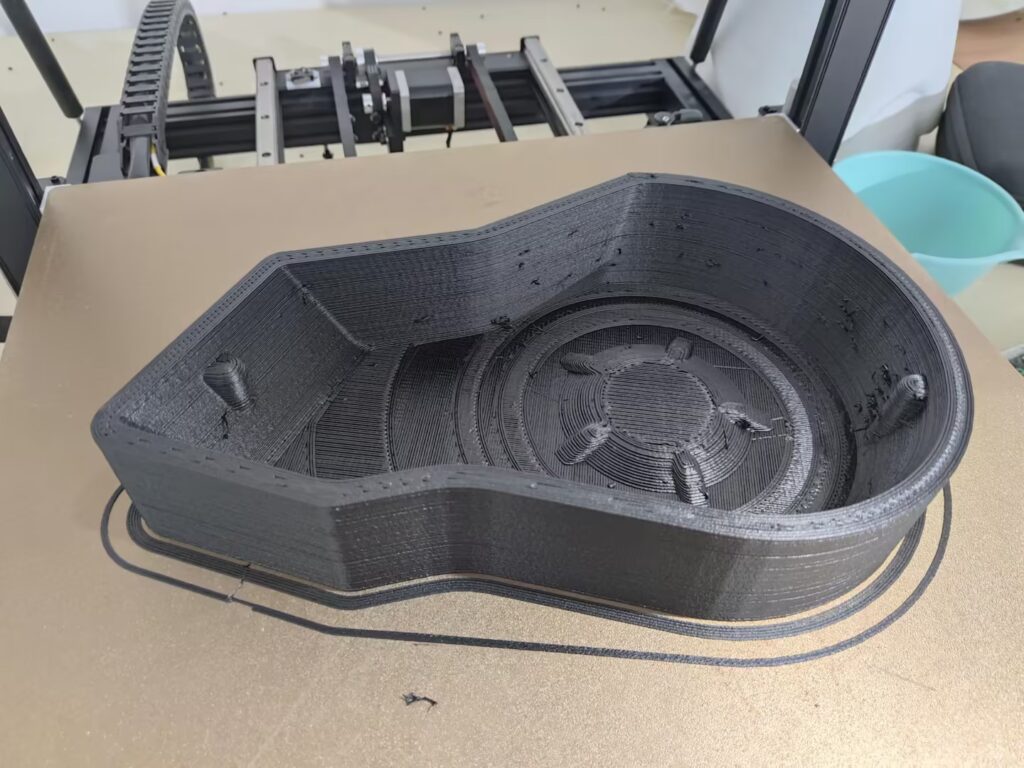

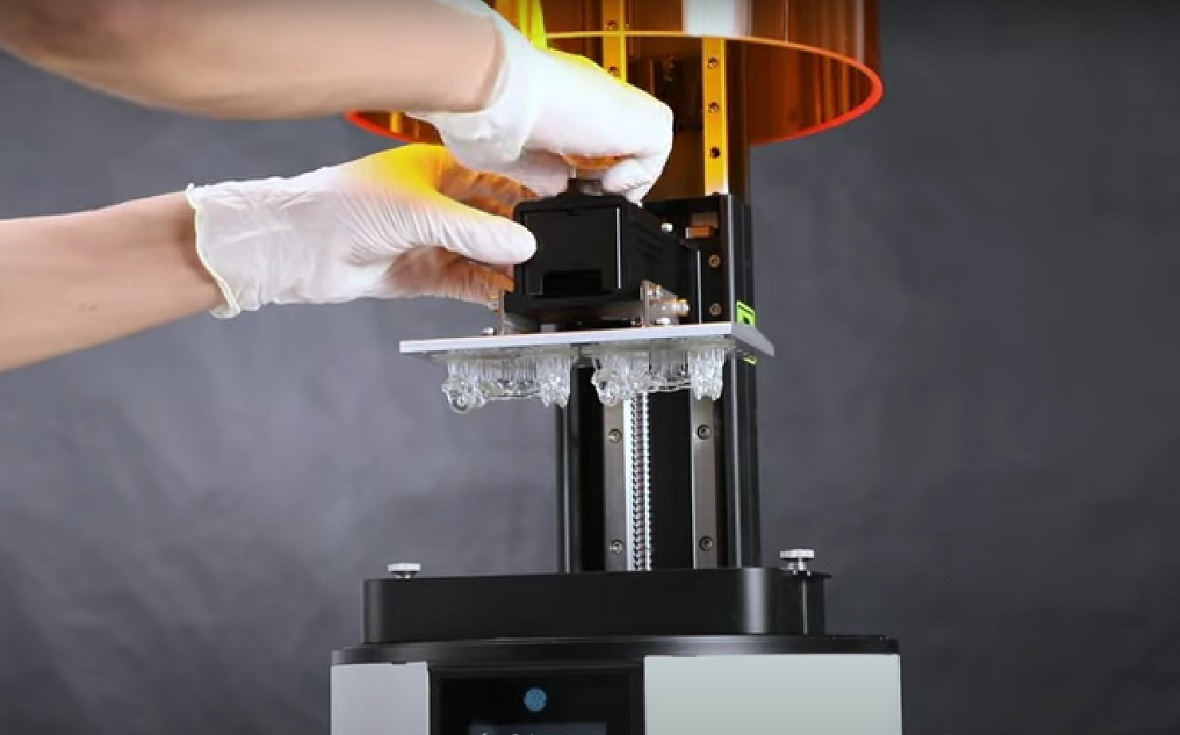

At GNYDM 2024, PioCreat introduced a lineup of advanced dental 3D printing technologies, including:

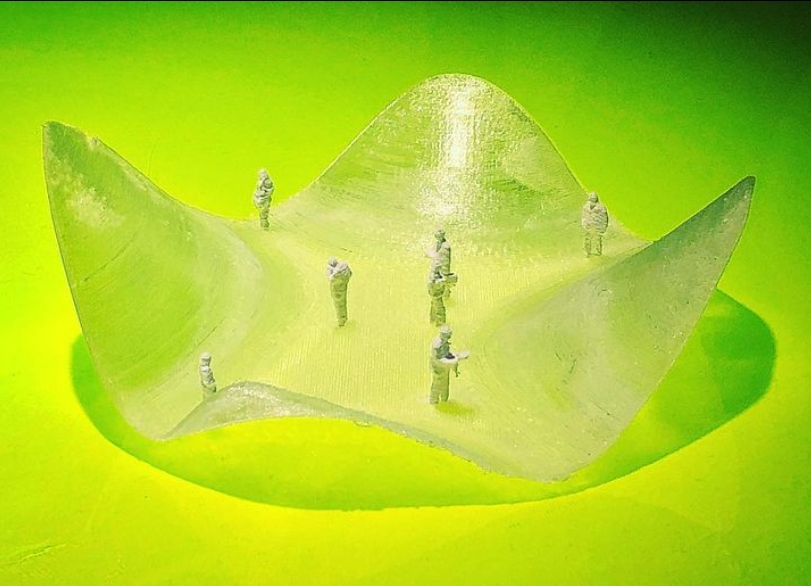

These innovations were complemented by live demonstrations of orthodontic models, removable die models, and surgical guide models, all produced with unparalleled precision and efficiency. Visitors were impressed by the possibilities these solutions bring to dental practices, from faster workflows to cost-effective production of high-quality dental appliances.

Delighting Visitors with Special Gifts

To express our gratitude to attendees, we prepared thoughtful giveaways, including custom-designed keychains and personalized medical flashlights tailored for dental professionals. These gifts served as a token of our appreciation and a celebration of the thriving dental community.

A Special Thanks to Global Synergy Advisors

We extend heartfelt thanks to our partner Global Synergy Advisors for their indispensable contributions throughout the event. Their expertise in integrating cutting-edge technologies into dental practices played a key role in presenting our vision for the future of digital dentistry.

About Global Synergy Advisors

Global Synergy Advisors is committed to empowering dental professionals with innovative, cost-effective solutions. By partnering with leading 3D printer manufacturers, they deliver advanced tools that enhance workflows and elevate patient care.