Pellet 3D Printer for Christmas Decoration Ideas

piocreat3d

on

December 25, 2023

The holiday season is upon us, and what better way to add a touch of innovation to your festive celebrations than with the groundbreaking Piocreat pellet printer! This revolutionary 3D printing technology not only brings a new dimension to manufacturing but also contributes to sustainability by utilizing various recycled materials. Let’s dive into the enchanting world of Christmas 3D printing ideas and discover how Piocreat’s pellet printer can turn your festive visions into reality.

Sustainability in Every Layer: Piocreat's Pellet Printer Feature

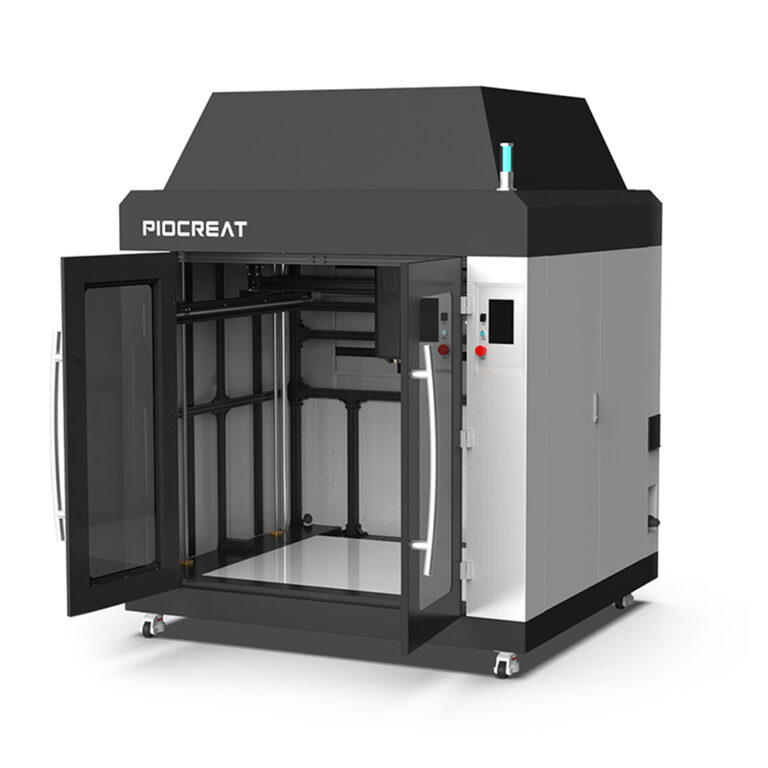

The star on top of the Piocreat G12 pellet 3D printer‘s Christmas tree is its ability to use a variety of recycled materials. Embracing sustainability, this feature not only reduces waste but also opens up a world of possibilities for creating eco-friendly and personalized holiday decorations. From old plastic containers to discarded packaging materials, your Christmas creations can now embody the spirit of recycling and environmental consciousness.

Beyond Manufacturing: Piocreat Pellet Printer Unleashes Creative Potential

Piocreat’s G12 pellet 3D printer isn’t just a manufacturing tool; it’s a gateway to turning your ideas into tangible, three-dimensional masterpieces. Imagine bringing to life custom-designed ornaments, personalized gift tags, or even a festive centerpiece that reflects your unique style. The pellet printer’s versatility empowers creators to explore uncharted territories, providing a platform for innovation that extends far beyond traditional manufacturing methods.

Deck the Halls with 3D-Printed Wonders: Christmas Decoration Ideas

Personalized Ornaments

Craft one-of-a-kind ornaments featuring family names, memorable dates, or even miniature replicas of beloved holiday symbols. The pellet printer allows for intricate detailing, ensuring your ornaments are as unique as the memories they represent.

Customized Gift Tags

Add a personal touch to your presents with 3D-printed gift tags. Whether it’s a miniature snowflake or a tiny Santa Claus, these tags will make your gifts stand out and become keepsakes for the recipients.

Festive Figurines

Create your own Christmas village with 3D-printed figurines of snowmen, reindeer, and jolly old St. Nick. Let your imagination run wild as you design and bring to life characters that capture the spirit of the season.

Advent Calendar Surprises

Elevate the anticipation of the holiday countdown with a unique 3D-printed advent calendar. Craft small, intricate surprises that will delight each day leading up to Christmas.

Santa's Workshop in Your Hands: Get Started with Piocreat

Ready to embark on your 3D printing adventure this holiday season? Piocreat’s pellet printer is your ticket to a world where imagination knows no bounds. Transform recycled materials into festive treasures, and let your creativity shine brighter than the holiday lights.

As you gather with loved ones and spread the joy of the season, let your 3D-printed creations become cherished symbols of the holidays. Wishing you a Merry Christmas filled with innovation, creativity, and the warmth of shared moments.