The Rise of 3D Printed Sculptures: Revolutionizing Art with Technology

piocreat3d

on

April 9, 2024

Table of Contents

3D printed sculpture is rapidly transforming the landscape of art, providing artists with unprecedented opportunities to bring their visions to life. The advent of 3D printing technology has introduced new possibilities for creating intricate, detailed sculptures that were previously difficult, if not impossible, to achieve using traditional methods. In this blog, we will delve into the world of 3D printed sculpture art, explore how 3D printers can produce sculptures, and discuss the benefits, materials, and best 3D printers for creating these modern masterpieces.

Overview: A New Era of Sculpting

Are conventional sculpting techniques and materials becoming obsolete? While many sculptors still prefer traditional methods, a growing number of artists are embracing 3D printing to create innovative sculptures. The technology has made significant strides in various fields, including prosthetics and architecture, and artists are no exception. By utilizing 3D printing, they can create intricate designs and experiment with new forms and materials.

Can 3D Printers Print Sculptures?

The question can 3D printers print sculptures? is an intriguing one that highlights the technological advances in the art world. The answer is a resounding yes. Modern sculpture 3D printers are capable of producing highly detailed and complex sculptures. These printers use a variety of technologies, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), to create sculptures layer by layer from digital models.

3D printing allows artists to experiment with forms and structures that would be incredibly challenging to carve or mold by hand. It opens up a realm of possibilities for creating both abstract and realistic sculptures with unparalleled precision. Additionally, 3D printing enables artists to easily replicate their work, making it accessible to a broader audience.

Benefits of 3D Printing Sculpture with Pellets

Cost Saving

One of the most significant advantages of 3D printing sculpture with pellets is cost savings. Pellets are considerably cheaper than filaments, often costing 65% to 90% less. This makes large-scale projects more financially feasible, allowing artists to experiment without worrying about prohibitive material costs. This cost efficiency extends to the reduction in waste generated during the printing process, as pellets can be easily managed and recycled.

Faster Print Speeds

Pellet-fed 3D printers offer faster print speeds compared to filament printers. The large heat zones in pellet extruders enable nearly 100 times greater material throughput, resulting in up to 200 times faster print speeds. This efficiency is particularly beneficial for artists working on tight deadlines or large installations. Faster print speeds mean that artists can iterate their designs more quickly, making adjustments and improvements in real time.

Larger Print Sizes

Creating large art pieces is often only economically viable with the use of cheaper materials and faster print times. 3D printers coupled with pellet-fed extruders are ideal for producing large-scale sculptures. These printers can handle substantial print volumes, making it possible to create impressive, oversized works of art that would be time-consuming and costly to produce by traditional means. The ability to print large objects seamlessly without the need for assembly is a significant advantage for artists.

Environmental Benefits

3D printing with pellets also offers environmental benefits. Initiatives like Print Your City help collect plastic waste and transform it into public park benches using 3D printing. Companies like Covestro sell recycled plastic shreds for use in pellet printers, promoting sustainability and reducing plastic waste. This eco-friendly approach is not only beneficial for the environment but also aligns with the growing demand for sustainable art practices. Artists can use recycled materials to create their sculptures, contributing to environmental conservation efforts.

What Material is Used for Pellets in 3D Printing Sculpture?

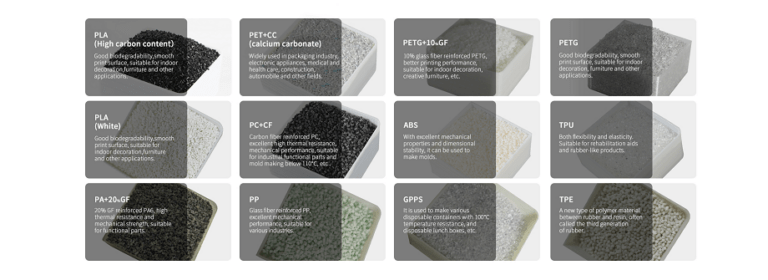

Artists have a variety of options when it comes to choosing materials for their 3D printed sculptures. Two of the most popular materials are PETG and ABS pellets.

PETG Pellets

PETG (Polyethylene Terephthalate Glycol) pellets are favored for their durability, clarity, and ease of use. They offer excellent impact resistance and are less prone to warping compared to other materials. PETG is also recyclable, making it a sustainable choice for environmentally conscious artists. Additionally, PETG’s transparency allows for unique aesthetic possibilities in sculpture, such as playing with light and shadow.

ABS Pellets

ABS (Acrylonitrile Butadiene Styrene) pellets are known for their strength and toughness. They are ideal for creating robust and durable sculptures. ABS can withstand higher temperatures and has good chemical resistance, making it suitable for outdoor sculptures or installations in demanding environments. ABS pellets also provide a smooth finish, which is beneficial for artists aiming for polished, professional-quality sculptures.

Best 3D Printers for Sculpture

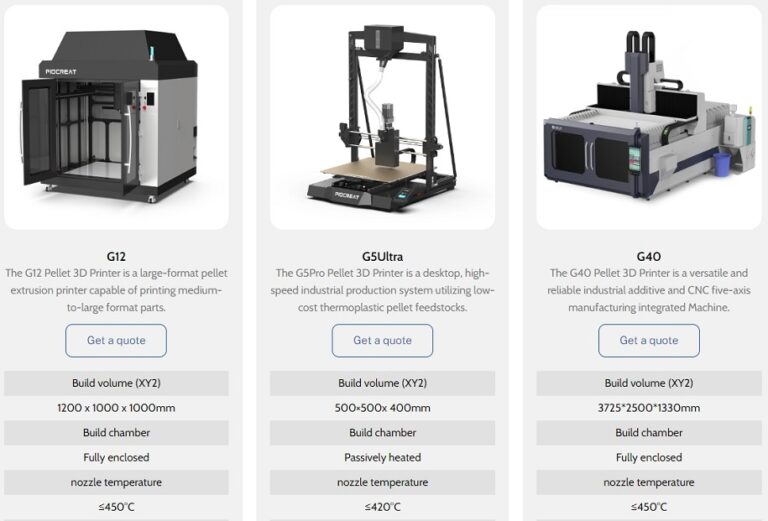

When it comes to choosing the best 3D printer for sculpture, two models stand out for their capabilities and performance: the PioCreat G12 Pellet 3D Printer and the G40 Pellet 3D Printer.

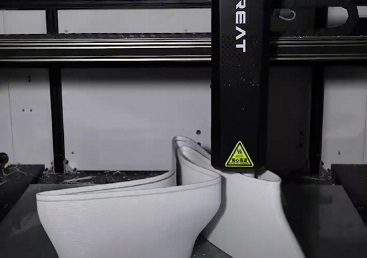

G12 Pellet 3D Printer

- Printing Size: 1200*1000*1000mm

- Features:

- Nozzle temperature up to 450℃

- Rapid heating of the hot bed up to 120℃

- High Flow Screw Extrusion

- Powerful Servo Motor

The G12 Pellet 3D Printer is a large-format pellet extrusion printer designed for medium-to-large format parts. Its high-performance features and robust construction make it ideal for creating substantial sculptures with intricate details. The G12’s capabilities ensure efficient and consistent printing, making it a favorite among artists and manufacturers alike. The powerful servo motor ensures precise movement and high-quality output, while the rapid heating capabilities allow for quicker start times and reduced downtime.

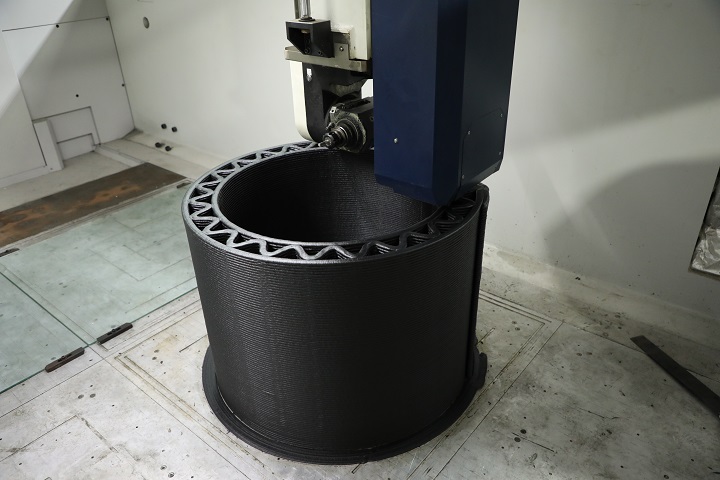

G40 Pellet 3D Printer

- Printing Size: 3725*2500*1330mm

- Features:

- Large working space

- Workbench design

- CNC five-axis head

- High flow screw extrusion design

The G40 Pellet 3D Printer is PioCreat’s largest industrial printer, offering a versatile and reliable solution for large-scale 3D printing. Its CNC five-axis head and extensive working space make it suitable for creating massive sculptures with complex geometries. The G40 is a powerful tool for artists looking to push the boundaries of 3D printed sculpture art. The large working space allows for the creation of life-sized sculptures in a single print, eliminating the need for assembly and enhancing structural integrity.

Expanding Further: The Artistic Potential and Future of 3D Printed Sculpture

Artistic Flexibility and Innovation

3D printing technology offers artists unparalleled flexibility and the opportunity to innovate. Traditional sculpting methods often require significant physical effort and time, which can limit an artist’s ability to experiment freely. In contrast, 3D printing allows artists to quickly iterate their designs and explore new concepts without the constraints of manual techniques. This freedom encourages creativity and can lead to unexpected and groundbreaking works of art.

Collaboration and Community

The intersection of technology and art in 3D printing also fosters collaboration among artists, engineers, and designers. Communities of artists and makers often share their designs and techniques, leading to a vibrant exchange of ideas and advancements in 3D printing technology. Collaborative projects between artists and 3D printing firms can result in innovative sculptures that push the boundaries of both art and technology.

Educational Opportunities

3D printing technology provides valuable educational opportunities for aspiring artists and students. Learning to create digital models and operate 3D printers equips students with essential skills for the future. Educational institutions increasingly incorporate 3D printing into their art and design curriculums, preparing the next generation of artists to harness the full potential of this technology.

Future Prospects

The future of 3D printed sculpture is bright, with continuous advancements in 3D printing technology and materials. Innovations such as multi-material printing and bio-printing could open up new possibilities for artists, enabling them to create sculptures with varied textures, colors, and even living elements. As 3D printing technology evolves, the line between digital and traditional art forms will continue to blur, leading to a richer and more diverse artistic landscape.

In conclusion, 3D printed sculpture is revolutionizing the art world by providing artists with new tools and techniques to express their creativity. The benefits of cost savings, faster print speeds, larger print sizes, and environmental sustainability make 3D printing an attractive option for artists. As technology advances and more artists embrace 3D printing, we can expect to see even more innovative and inspiring sculptures that push the boundaries of what is possible in art.